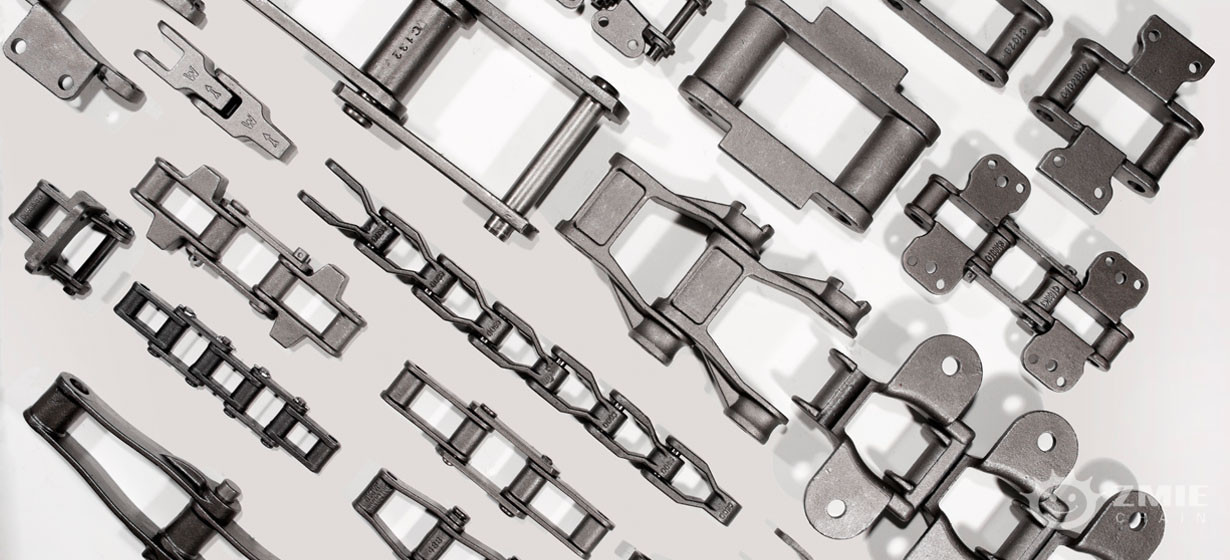

Conveyor Chain

Conveyor chains can vary widely depending on direction of transport, application environment and transported media..

Downtime for your conveyor system can be costly and cause your facility to fall behind on important operations.

Which is why you need a chain manufacturer who has experienced it all.

ZMIE provides high quality materials and manufacturing methods to suit the most arduous of conveyor chain applications.

Performance, durability, safety and consistency typify our conveyor chain solutions.

download

Engineering Class Chain

Zmie Enginnering class chains are applied when drives need to move very heavy equipment and withstand shock loads.

Each part of the chain are used the latest manufacturing and heat-treating techniques to manufacture and each part is carefully machined to close tolerances to ensure the longer lifetime.

Zmie Enginnering class chains include crank link drive chain, steel bush chain, cane carrier chain, deep pan conveyor chain.

download

Roller Conveyor Chain

Rollerconveyor chain systems have been in use for decades, and are the preferredmethod for moving heavy boxes, pallets and machinery from place to place.

Conveyorchains are used in a variety of applications as diverse as food service andautomotive parts. Historically, the automotive industry has been a major userof this type of transportation of heavy items between various stations within awarehouse or production facility.

The sturdy chain conveyor systems present acost-effective and reliable method for boosting productivity by keeping itemsoff of the factory floor.

Conveyorseries roller chains are one of the most widely used types of chains in theworld. Because of this, we stock almost every size and configuration rangingfrom ANSI, DIN, and ISO certified series chains

download

Bucket Elevator Chain

Bucket elevators are used to lift aggregate material to the start of gravity fed processes in many industries and are a critical application for many operations.

The buckets are installed on a vertically circulating chain, to vertically convey loads of granular powder.

ZMIE bucket elevator chain is the ideal chain for conveying cement and corrosive coal fly ash.

The connecting links of bucket elevators chain are easily to assemble.

ZMIE bucket elevator chain use high-quality steels for maximum wear life and toughness.

download

Welded Steel Chain

Welded steel chains are of offset sidebar construction and do not have rollers, ideal for high impact and abrasion resistant conveying applications. Typically welded steel chains are found in forestry,agricultural, municipalities, grain handling, cement industry, and a wide range of medium to heavy-duty conveyors around the world.

Side bars and barrels are medium carbon steel. Pins are medium carbon alloy steel and are thru hardened for maximum chain life. Pins can be induction hardened for even more wear resistance. The WH chains also have thru hardened sidebars and barrels for greater strength and wear resistance. All parts can be furnished with additional heat treatment on request or as the operating environment requires..

Most common sizes are available and can be provided with welded attachments.We also have stainless steel welded steel chains for abrasive and corrosive applications.

download

Enclosed Track Chain

Enclosed track conveyor is a series of trolleys with a load, suspended by an overhead track and connected to a continuous running chain, which can run winding both horizontally and vertically.

The advantage of the enclosed track design is to prevent contamination of the conveyor chain.

The enclosed track protects the chain against build-up and residue that could ultimately cause damage, and the enclosed track negotiates curves and changes in elevation to maximize use of overhead space and confined areas.

ZMIE has a wide variety of Enclosed Track Chain for many different applications.

download

Case Conveyor Chain

Case conveyor chain used in a variety of applications.

All chain components are heat treated to achieve greater durability and extended chain life.

Designed for greater flexibility in horizontal and vertical movements.

Case conveyor chains are suitable for harsh environments, and their open construction allows the easy removal of coarse dirt. Case conveyor chains are frequently used for barrel / container conveying, in the construction materials industry, for pallet conveyor systems or in carwashes.

download

- Conveyor Chain

- Roller Chain

- Drop Forged Chain

- Sprockets

- Components