ZMIE, as professional team in conveyor chains, drop forged chains, roller chains , sprockets field over 20 years, Will present you with qualified but cheaper solutions. By carefully selecting matching partner workshops, with Senior technician team on sight control, will save your budget and enrich your work with personal care.

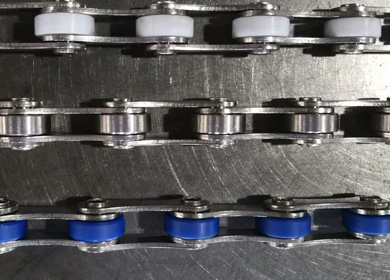

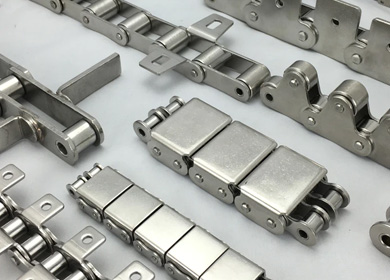

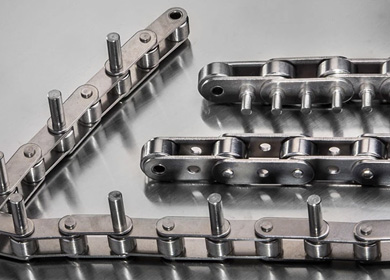

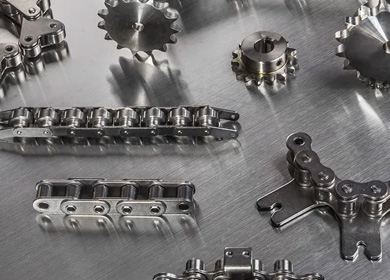

ZMIE conveyor chains, drop forged chains, roller chains and sprockets are used in any moving fields. Wherever things needs to be lifted, moved, rotated or conveyed, our chains and sprockets will appear.

Since 2003, ZMIE team with over 10 year experiences provides high-quality Roller Chain, Drop Forged Chain, Conveyor Chain, Welded Steel Chain, Enclosed Track Chain, Sprockets, Component, etc.Write us your requirement.